Scanning challenges

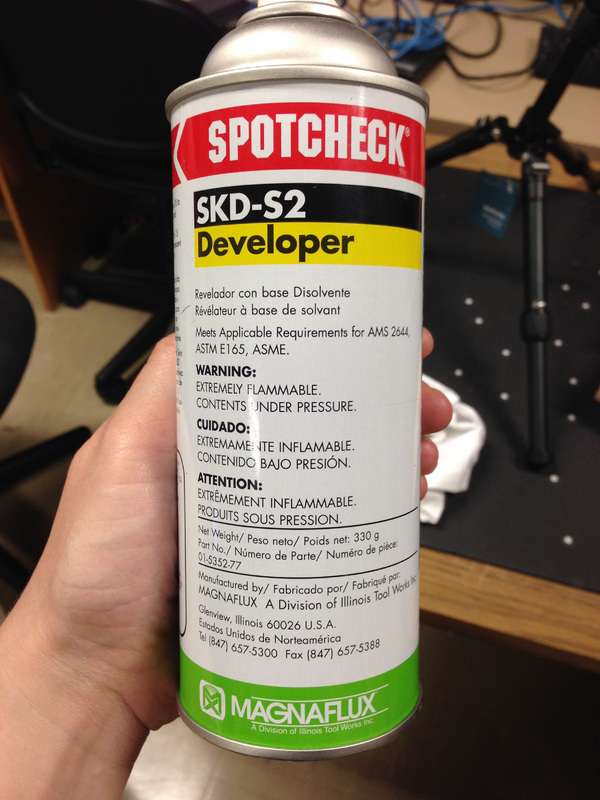

Unfortunately almost all of the instruments in the vet bag are made of glass, chrome and metal which are highly reflective. 3D readings are not possible with shiny objects as the light used to make the readings for the scans is reflected from the object. To surmount this problem, an aerosol spray of fine white powder was used to coat the instruments before they were scanned. This allowed for rendering of better scans, but introduced the need for post-scanning work to map materials to the white scans of the objects.

Aerosol spray used for coating reflective objects

This procedure worked well to render the shape of the object and provide a good sense of its geometry, but the film of powder obscured some of the detail on objects such as the Inspector’s Badge. The badge is engraved with words that harder to decipher once the powder is applied.

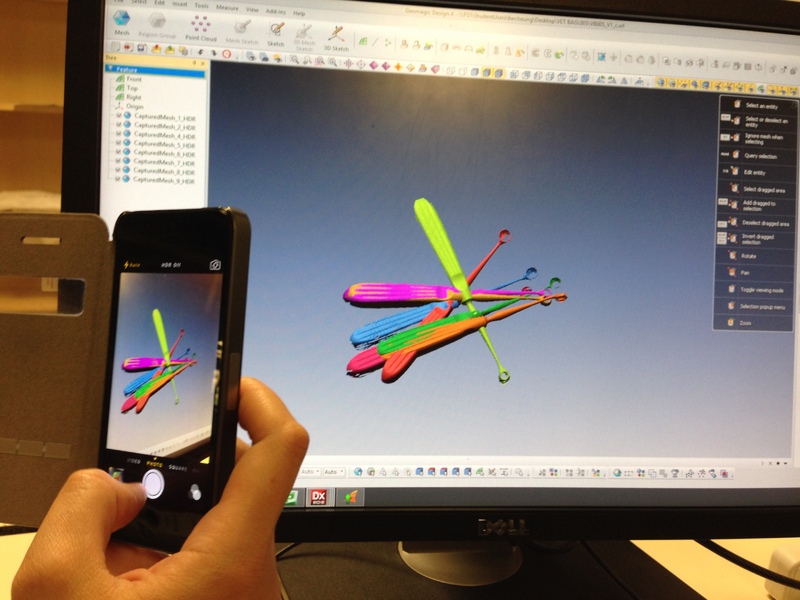

Post-processing of scanned image

Viewing Challenges

The files created from the scanning are .obj files that require special software for viewing. Initially the plan for these scans was to integrate them with the Omeka software that was being used to create the Winnie Collection website. Omeka has a series of plugins that can be used to extend its functionality but nothing designed specifically for working with 3D scans.

Because we weren’t able to load .obj files directly into Omeka, another viewing solution was required. Sketchfab is a site, a YouTube of 3D images, which can be used for hosting 3D images. The .obj files were loaded to Sketchfab and tested in Omeka using embed codes in simple html pages. Later our developer created a way to use the unique Sketchfab identifier to add the 3D scan to the item records in Omeka using a new item type.

The 3D scanning component of this project has given us a better idea of how this technology can be used in virtual exhibits. We have a clearer sense of how much time is involved and what the limitations of the technology are. We are interested in seeing how the scans are received by users as this will inform how we choose to proceed in our scanning projects. We also would like to explore other methods of scanning and hosting 3D models to find a solution that will work well for future projects.

Sally Wilson, Web Services Librarian, Ryerson University Library & Archives